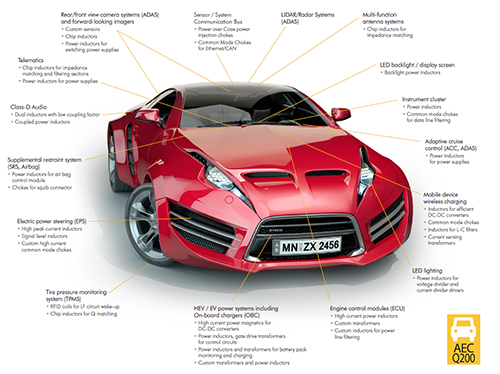

Coilcraft offers a wide range of off-the-shelf inductive components engineered to withstand extreme heat and cold. Most of them meet the stringent quality standards of AEC-Q200 and are suitable for use in harsh automotive environments. Automotive applications for Coilcraft inductors and other components include:

- Multi-function antenna systems

- Power over coax/LVDS

- Telematics

- Class-D audio

- ADAS

- LIDAR/Radar Systems

- Supplemental restraint systems (Airbag)

- Anti-lock braking systems

- Electric power steering systems (EPS)

- Tire pressure monitoring systems (TPMS)

- HEV / EV power systems including On-Board Chargers (OBC)

- Engine control modules (ECU)

- LED lighting

- LED backlight displays

- Adaptive cruise control (ACC)

- Instrument panel

This article discusses AEC-Q200 qualified inductors and the implications these and other passive components have on vehicle system performance.

What is AEC?

The Automotive Electronics Council (AEC) is a global council that includes many Sustaining Member automotive companies including Autoliv, Bose Corporation, Continental Corporation, Cummins, Delphi Corporation, Denso International America, Gentex Corporation, Harman, Hella, John Deere Electronics Solutions (Phoenix International), Kostal Automotive, Lear Corporation, Magna Electronics, Sirius XM, Valeo, Visteon Corporation ZF TRW Automotive and other Technical, Associate, and Guest Members.

The AEC council includes two committees:

- The Quality Systems Committee and the

- Component Technical Committee

The complete AEC-Q200 REV D (June 1, 2010) base pdf document "Stress Test Qualification for Passive Components" can be downloaded free-of-charge from the.

What is an AEC-Q200 inductor?

An AEC-Q200 inductor has passed the environmental stress testing requirements of the AEC-Q200 global standard. This standard tests the ability of passive electronic components to withstand the temperature and physical stresses of automotive environments. Automotive industry companies require the use of AEC-Q200 qualified components. Selecting AEC-Q200 qualified inductors eliminates the need for additional component qualification testing.

What are the temperature ranges covered by AEC-Q200?

Stress test qualification temperature ranges established by the AEC-Q200 standard are categorized into five grades (0 - 4), as shown below:

| Grade | Temperature Range | Typical Application |

|---|---|---|

| 0 | ?50°C to +150°C | All automotive applications |

| 1 | ?40°C to +125°C | Most under-hood applications |

| 2 | ?40°C to +105°C | Hot spots within the passenger compartment |

| 3 | ?40°C to +85°C | Most passenger compartment |

| 4 | 0°C to +70°C | Non-automotive commercial / industrial |

What AEC-Q200 tests apply to Coilcraft off-the-shelf inductors?

Table 5 (Pages 28 and 29) of AEC-Q200 Rev D (June 1, 2010) defines the test methods and additional requirements for magnetics, including inductors and transformers. These tests include a variety of methods to test the component's ability to withstand severe conditions, including:

- High temperature

- Thermal cycling

- Thermal shock

- Low temperature storage

- Moisture and humidity resistance

- 1000 hours at rated temperature and current

- Mechanical shock and vibration

- Constant acceleration

- Resistance to soldering heat

- Resistance to cleaning solvents

- Terminal force strength

- Shear strength

- Board flex

Representative component samples are also measured to verify that the physical dimensions comply with the datasheet specifications. In addition, they are inspected visually for construction, marking, and workmanship, and the electrical parameters are measured pre- and post-stress testing to verify conformity to specifications. This rigorous battery of tests assures that the AEC-Q200 qualified inductors are capable of handling the harsh conditions of the automotive environment.